Echo Environmental has developed several processes for utilizing

common e-scrap materials in cutting-edge methods to produce

useable products, while generating no landfill waste.

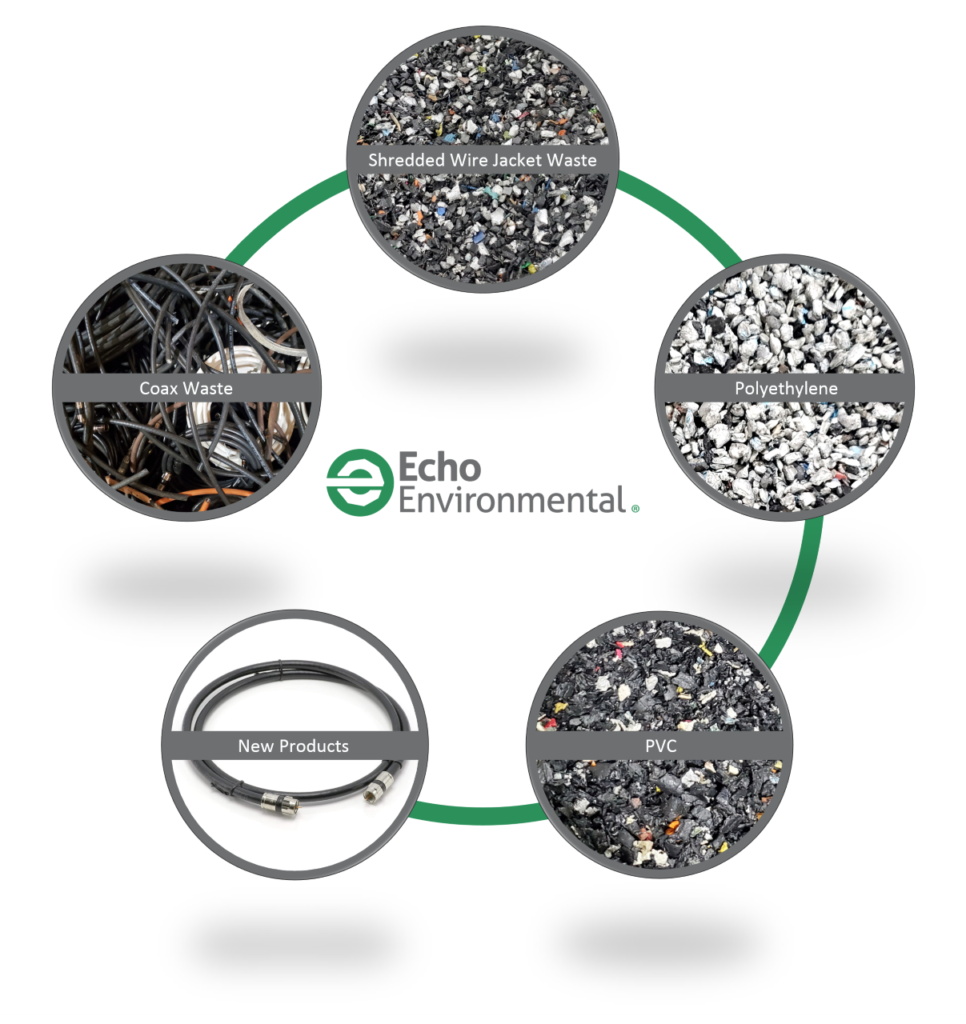

Our polymer recycling process is the reintroduction of a company’s waste materials back into its supply chain as new products. This is done by means of advanced, customized recycling solutions. Echo's cable processing facility converts traditional landfill waste materials, like jacketing and insulation, into high-purity, commodity pellets that can be used to manufacture new wiring.

Polymer Recycling

Echo’s polymer recycling process involves sorting shredded e-scrap plastics by their polymer type.

This technology gives Echo the ability to create high-quality, polymer fractions that can be reintroduced directly into the supply chain. This allows the production of new products such as cable box face plates, modem housing, and remote housings.

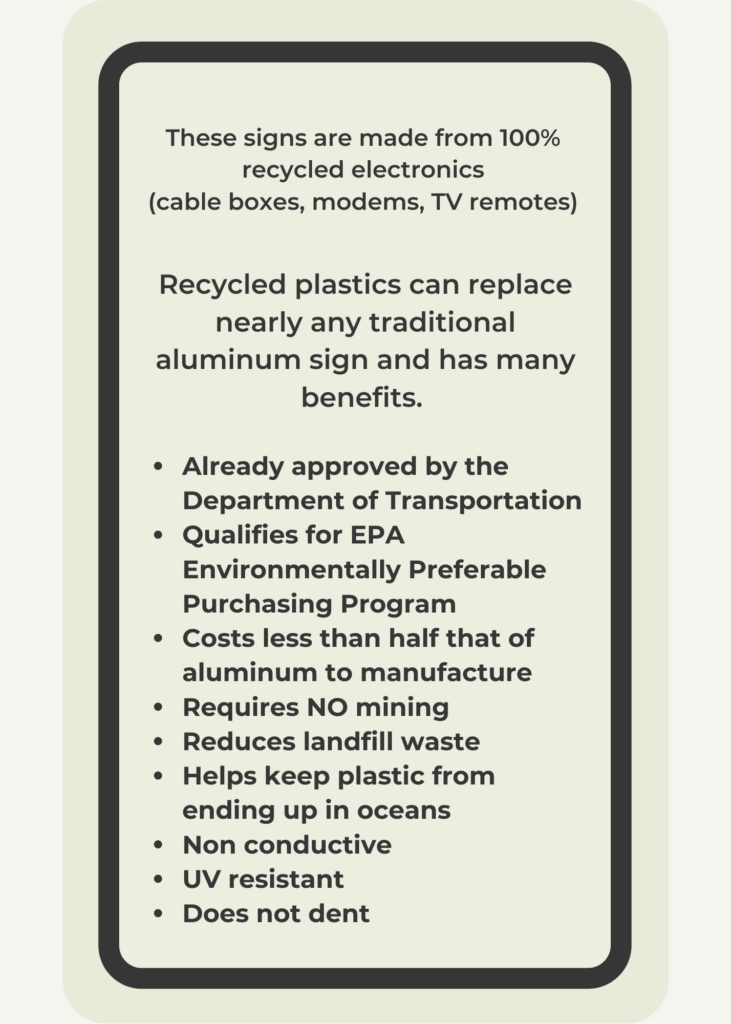

Materials will go through a profile extrusion program. This is a specific process that utilizes Echo’s in-house proprietary blend of recycled materials. The products produced from this program can be used as alternatives to traditionally supplied products such as campus signage, benches, support mats for utility work, and more.

The initial product produced from our plastic recycling plant is high purity PVC and Polyethylene pellets. These can be reintroduced into the MSO supply chain to manufacture new items. This true closed loop ecosystem is the ultimate objective for sustainability teams.

Signs

Extruded Lumber Products

Injection Molded Products

Turning negative-value waste into new, durable products